Trending

The REInterview: Social Construct’s founders on making multifamily construction an assembly line

Ben Huh and Michael Yarne on how their startup could allow developers to build faster, cheaper, and more predictably

“Nothing can be said to be certain except death and taxes,” goes the old chestnut. If you’re a real estate developer, you could add one more to that category: that your cost of building will keep going up.

The primary reason for this is the cost of labor. A construction site is a minefield of uncertainty, and the back-and-forth required to build housing in cities such as New York and San Francisco means that labor costs have ballooned over the years, with contractors just building that cushion into their estimates. That means developers pay more, housing costs more and takes longer to build, and fewer projects are built.

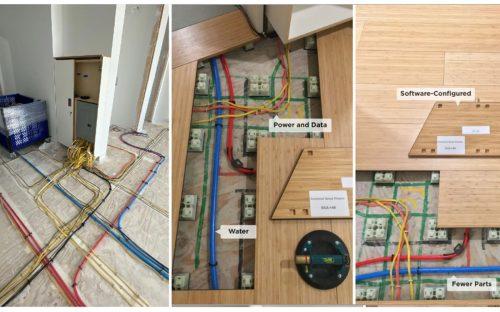

But what if you could code away a good chunk of that uncertainty? That’s what the founders of Social Construct, a new construction-tech startup, are promising. Led by Ben Huh, former CEO of meme empire Cheezburger, and Michael Yarne, a developer and former real estate advisor to the San Francisco mayor’s office, Social Construct uses software to generate floor plans, optimize electrical and plumbing and standardize on-site assembly. It claims that this “assembly line” approach to multifamily construction can cut cost and build time by up to 30 percent.

Social Construct, which closed a $17 million round from the likes of Founders Fund and Y Combinator in 2017, is now looking for a further $15 million in investment. The Real Deal caught up with Huh and Yarne to understand how software can cut fat on a construction site and lead to a boost in housing production in supply-starved cities.

This interview has been condensed and edited for clarity.

You’ve just emerged out of dark mode. Let’s get the elevator pitch.

Huh: We developed a technology platform that organizes multifamily construction into three different stages: the site, the shell, and the internals. That approach, and the technology we’ve built with hardware and software, allows us to actually build on site much more efficiently, as if we were building an assembly line process.

Is that the next iteration of modular housing then, or is it taking that forward? There have been some very high profile failures in modular housing.

Yarne: Thank you for offering us that distinction.

Huh: Modular construction has a very interesting history and one that we’ve invested a lot in as an industry, and there will be a place for that. But we think that the vast virtue of the market is actually better served by using in situ techniques, right? It’s just that labor costs and inefficiencies haven’t kept up with our expectations.

We are not modular construction, far from it. We are trying to develop a whole new branch of construction that is more closely related to conventional than we are off-site, factory, containerized.

So your approach is much more focused on understanding individual sites, individual challenges in different sites and then going from there. How else would you distinguish it from modular?

Huh: We’re an ecosystem approach. We believe that general contractors, subcontractors, local developers know best about their local markets and their local environment, and we want to actually incorporate that into our framework and our platform. We don’t actually turn on cars in the factory and expect that those boxes or cars will work everywhere. These are buildings, buildings are naturally inherently local to the environment, and local input must be respected. We want to respect the architect’s ability to actually adapt the structure and the design for the demands of that local market as well.

Yarne: We’re more Legos and the prefab modular is Duplo, the big blocks. More specifically, we apply our Legos in the shell on the internals, but the site is the most unique of all, right?

In San Francisco, where Ben and I live, literally you could go 500 feet and have a completely different foundation be required. Because there’s a former wetland that requires massive piles. Then there’s a site 500 feet from where I live that’s on bedrock. So if you’re standardizing, like we are, that would be insanity to suggest a standardized approach for site.

You are starting in California which has to be among the most contentious places anywhere in the world to build anything, particularly of scale. Are you working with individual developers or contractors on a site-specific basis trying to understand challenges on each site and then designing, “Hey, let us come and assess the site and assess your needs and come back to you with a model”?

Yarne: We made a tactical decision to self-develop our first several projects. There’s so much learning when you first do something that we thought it would be better to internalize a lot of that risk. We have a private-equity partner who is the actual JV LP partner – they bought 95% of the project.

So you did all the approvals, and the entitlements, and all of that. What was that process like? When you went into the room, into the City Council, and said, “Here’s what I’ve got in mind.” How did that look?

Yarne: We made our first project beautifully small. That size afforded us a very smooth approval process. One, the site was already entitled when we bought it, so we just modified the entitlements. Two, Oakland is a far easier entitlement environment than San Francisco. I feel like I’ve been training at high elevation, because all my projects are in San Francisco, everything is a melodrama. Then you go to Oakland, and the city government has done a lot to make multifamily development efficient.

In San Francisco, pretty much every decision is discretionary and every decision, including putting a hot tub in your backyard, can go to the Planning Commission. You can have appeals with lawyers about hot tubs.

But to make this work as a business and at scale, you’re going to have to play in these dirtier markets, right? San Francisco and New York, where what you want to tackle is the affordable housing problem.

Huh: This is where technology really makes a difference. One of the reasons why I think people have difficulty and delays and cost overruns and fear around development is that development is an uncertain thing, because design changes, and every decision they make is shrouded in mystery. If we need to change the facade, the amount of time it takes to go get bids, and to go do that work is actually very expensive, and it takes a long time.

This is where a system like ours can actually accelerate that process. Changes on accommodations occur much faster, and so the risk taking that has been taken today is not as necessary when the system actually updates almost in real time.

A lot of those changes happen in so many unpredictable parts of the construction process. City Council may send you back on something small, then there may be community opposition to a certain other part of it. So you’re going back to the software each time and making those tweaks in a way that’s cheaper?

Huh: Let’s say you could actually design a building in real time. I put a bedroom here, a bathroom here, and you didn’t have to worry about where the MEPs [mechanical, electrical, plumbing] went, whether structural engineering has to change. If you could calculate that in real time, those adaptations are like editing a Google Doc together. We don’t have to worry about these things because technology has abstracted out the complexity by automating it behind the scenes.

Yarne: When you have a design change, it ripples through the entire mechanical, electrical, plumbing engineering team, the structural team. So it’s not as simple as an architect saying, “I’m going to set back the fourth floor to accommodate that neighbor’s desire for no shadow.” It has a massive ripple effect. It’s not just the time it takes for all of those designers to coordinate- it’s the ability to generate reliable bid costs. Our platform is automating a huge amount of that.

You’re right. Architects are often at the mercy of their developers who are at the mercy of the general contractor, who’s at the mercy of the subcontractor, and there’s so many fault lines in that process. But you’re telling them that at each fault line we could just go back and code this out?

Huh: Absolutely. It can generate the drawings, and the permits set to a level of fidelity that would take hundreds of hours of engineering time to do.

Yarne: As we grow and scale and we have more and more data from labor time, we won’t just generate a transparent bill of materials – I call it the IKEA shopping list, “Oh, this is what this design needs.” But it would also generate increasingly statistically significant labor estimates.

We’re treating the carpenter like our user. We’re looking at what makes life easy for the installer and we’re measuring every minute of time. The carpenters are like, “What, you actually want to talk to us?”

Isn’t that a little naive though? We’re assuming here that the contractor has the agency to determine how the job is done or what is used, whereas in at least in the big cities the power doesn’t flow from the worker.

Yarne: This is important. I’m talking about the actual laborer. If we have real-time data from the laborer, we can actually more effectively manage the subcontractor owner. One of the problems I ran into as a developer is the opacity of these bids, right? In San Francisco, it’s gotten so bad that the electrical or the plumbing subcontractor will just say, “It’s $40,000 a unit.” You’re like, “How much of that is wiring?”

Huh: When I approach this problem I’m looking at it and going, “Okay, how would we solve this if this had to be a manufacturing assembly line scalable process?” The reason that you have means and methods that do not work on the site is because no one has actually tested that means and methods for that specific space. We go in and say, “Okay, let’s eliminate 99% of the variation that has zero value.” What would that system look like? Can we make a riser that goes straight up and down in a stud bay? How do we separate out the complexity from the walls into the floors into our manufacturing system, so that you follow a “paint by numbers”? We want people to “construct by numbers” using our system, and we’re trying to make sure that it’s not just us pushing that down to them, that we agree that that is the methodology we’ll use.

Yarne: I don’t want to make out subcontractor owners as evil or something. I’m not, but they do like to make money. But one of the things that you see in their bids is they’re pricing in all of the arbitrary unknowns. Part of the reason they pad their bids so much, one, is broken labor markets, we can get into that in a minute, absolutely. These are cartel-like labor markets.

We realized that there are power imbalances all over the place, but the inefficiencies are best solved if the system understands what the work is. — Ben Huh

But one of the other more legitimate reasons, is that they encounter such arbitrary job site conditions. So they build in extra budget specifically so they can avoid fighting over change orders, etc.

Huh: We realized that there are power imbalances all over the place, but the inefficiencies are best solved if the system understands what the work is.

That’s a fascinating point. Have you both considered the politics of this? Construction unions are among the most politically connected and powerful entities. You can follow the timeline from when a union says something to when the governor of New York says something, the same thing kind of happens in California. How are you going to withstand some of the fire that would come your way?

Yarne: I worked for two mayors in San Francisco. I think it’s safe to tell you right out of the gate, we have a phenomenally close relationship with the Northern California Carpenters. The carpenters are the largest of the building trades unions. They have the largest membership and the fastest growing membership.

By some amazing cosmic occurrence, they are very innovative and recognize that their industry needs to change. We’re committed to using union carpentry labor. Those union carpenters, the wages and the benefits are actually some of the best in the country. Here’s the great secret, because we are achieving productivity.

In the TechCrunch article, one of you said, “It’s going to be overall more work because they’ll have more projects.” In California, this is the hard thing, to actually get a project to construction is a massive task. You’re assuming that volume will go up with efficiency?

Huh: Yes. A lot of it has to do with the risk. As a developer, you have to worry about escalation, contingency. You have to worry about the delivery risk, market-timing risk, all of that. So once you actually have a system that becomes much more reliable in your ability to deliver at the cost and schedule level, that risk can be kept. Then you have a revolutionary approach to how you address the needs of the real estate market.

Yarne: I want to share some also somewhat humbling information. Right now in the Bay Area, there’s no shortage of entitled projects. But the real estate economics are upside down. Before COVID we were already in this place, it’s now even worse. Hard costs have continued to escalate at unsustainable levels. And rents had already softened, right? Now, as you know, they’re collapsing in the high-cost cities.

The reason those escalations have been happening is not that glass, steel, and wood have been escalating 7 percent every year. It is 1,000 percent labor and most importantly, markups on labor.

There’s no shortage of entitled projects. But the real estate economics are upside down. — Michael Yarne

When I say labor, I don’t mean the guys or women earning the wages. I mean, the total cost including the markup. Because people think when we’re saying “labor is outrageously expensive,” that we’re actually suggesting that wages are too high.

You’re not trying to replace the bodega like that startup that came along.

Yarne: That was a lovely startup.

Huh: Tech definitely has some insensitivity towards small businesses and this is where our approach differs. We’re trying to figure out “how do we help them increase their productivity?”

Let’s talk a little bit about the pandemic and whether it’s proved your value proposition in a way. The one side I could see is that there’s an immediate need for less complexity on a job site, right? But the flip side of it is that, your model, I’m assuming, relies on density and asking cities to get denser.

Yarne: Wherever there’s a need for multifamily, we’re going to be offering value. Markets like Charlottesville… the market perception was there wasn’t a construction cost problem in Charlottesville. Let me tell you that in these so-called second-tier or third-tier cities, Nashville, Austin, etc., they’re having the exact same problem.

We’d love to Zoom build, but some construction worker in North Dakota can’t Zoom build in San Francisco. They literally have to move their body there, right? This is the thing I think a lot of folks don’t get is, construction labor markets are inherently regional. We’re seeing pretty much everywhere a shortage of skilled construction labor.

Huh: How it [the pandemic] has accelerated our launch is because we are using mass timber, wood frame on-site, walkable neighborhoods without the huge density that megacities require. Which is exactly what the market is needing right now, when people want to go into smaller cities with walkable neighborhoods.

You don’t need to talk specifically about your competitors, but I will. You’re really in that emerging field of construction tech which has seen a lot of money flow into it, but there have been a couple of very serious setbacks. I’m thinking about Sidewalk Labs, which pulled the plug on its Toronto project. Then Katerra, SoftBank-backed, raised a couple billion dollars, mass layoffs, many projects haven’t been completed. What does that do for the perception of your business?

Huh: So I used to be in the memes business.

Oh, I know. [Huh was CEO of the Cheezburger Network (I Can Has Cheezburger?), a meme empire]

Huh: We were at one point one of the largest media networks on the internet, and it’s given me a very unique insight into “Honey Badger Don’t Care.” There have been setbacks throughout history of large, well-capitalized people or industries. I don’t take any joy in watching them, because it certainly does make the job harder. However, as a small tiny little startup who’s taken a very unique perspective and a unique approach, we can point to them and say, “That’s not what we’re doing.”

We’re not trying to manufacture giant cities from scratch. We’re trying to prove that it works at this small scale, because we know that technology is really good at scaling stuff. We’re going to apply scale after we figure out the technology.

From the list of investors that I saw, you went more of the traditional venture route, which makes me believe you were probably betting on your track record as a successful internet guy. Are you looking at the industry as well for money?

Huh: We’ve proven our system to a point where it’s no longer a weird thing being done by a stranger from the outside industry. Now we can point to a building, take them on a tour, show them our technology, show them our progress and say, “Hey, we are believable. You can trust us to actually scale this to the next level.” And that’s where I think the strategic partnerships with real estate come in, and so yes.

Yarne: If we had raised money from the real estate sector initially, they might want us to look and quack more like a duck, and we don’t.

Because it’s not their [traditional venture investors] pond, they don’t teach you how to swim in the same way.

Huh: They don’t get worried when you quack or when you squeal or when you fly. They’re like, “Well, should you be doing that? I don’t know.”

They don’t get worried when you quack or when you squeal or when you fly. — Ben Huh

For this to work as a venture backed business, I’m guessing licensing is the way forward?

Huh: We are a design-build engineering firm with superpowers. We can scale that. Using the technology, there will be a single person who you can talk to who’s going to help you with your project that will help make sure the GC has their technical questions answered. So there’s a service component to it, because every project is going to be different. The dollar figure associated with this industry is so high, this part even boggles the VC’s mind.

But we’re not selling a $4,999 a month subscription to a software platform. This is a $75 million hard cost project in which we could save you millions of dollars. That’s where the value proposition of having service, a technology enabled service, really does scale. You’re not going to buy an enterprise software solution without being able to call someone. It’s not just Gmail, this is absolutely a high-touch product with high margins for us.

In that scenario, how are you making your money?

Huh: We bid a project out, we guarantee the cost, we guarantee the schedule. You pay us a fixed fee for the entire project, and we manage it for you.

This is where the technology part is really interesting. Once you start to realize that the difficulty of construction is in the variations and the little details, and you can actually standardize that and make that automated by software, it only takes one person per project at the most, to help shepherd that through, because we’re not the GC. We’re not the subcontractors, those people are doing the work, we’re making sure that their work is being done correctly according to our system, that the supply chain is flowing correctly.

You’re answerable to the developer?

Huh: Absolutely. And we want the developer to call one person with every problem, and we can actually go help handle that for them. We don’t want the developer to go figure out, who screwed this up.

Who we’re really going after now and really providing value for is a smaller organization. A small development organization that has land, that has entitlement, whose numbers aren’t working out because the construction costs are too high, or the risk is too high, and they can’t get the loans that they would have been able to get had this been a different economy. That’s what’s actually driving our desire to make sure that they can get the service and the technology that they need, because the bigger operations already have some economies of scale they already have.

They’re already quite vertically integrated. They often own a part of the supply chain as well.

Huh: That’s right. That’s the part where we look at the market and say, “If we want to do walkable neighborhoods, and we want to do beautiful buildings that are small or smaller than what’s happening in larger cities, then that’s who we have to actually support.” Not only the GC and the subcontractors, but people who want to do a 90-unit or 120-unit building, not 600 units.

And even just that market is so huge. I typically hate that TAM [Total Addressable Market] figure, but do you have one?

Huh: Let’s put it this way. The average entitled multifamily project just in the city of Oakland is 175 units. The median is 90 units. There are more than 60 projects under that 90-unit mark alone in just the city of Oakland. So that’s a massive number in a secondary city, and you can think about how that replicates all over the coastal United States, and all over the hot markets.

I want to ask you about financing. Construction financing typically works in tranches and construction milestones; you’ll get the first chunk of money when you hit a certain milestone, another chunk of it when you hit another milestone. Your model is going to change that a little bit, right?

Yarne: There’s a couple answers. First of all, we chose a beautifully traditional construction lender for our first project. First Republic, privately owned bank, small is beautiful. Surprisingly, the construction lenders looked at it like any other construction project. They might have not given us as high a loan-to-cost ratio as a more conventional project would have gotten, but the good thing about the construction lending industry, they’re kind of like herd cattle. If one cow is going to the water, then they’ll all go to the water, because they’re like, “Oh look, they delivered, they actually met their schedule.”

But your milestones are different?

Huh: Actually they’re not. Again, this is where like we’re mewing like a duck, it’s really bizarre, because of our approach, because we’re not this prefab modular system that shows up at a factory and you got to pay all the people in advance. We appear very much like a conventional project, you show up to the site, it looks mostly like a conventional project- just better organized with faster installation. The risks and the timelines and the draws actually are very similar to conventional, and this is actually by design. We recognize the difficulty of a real estate developer having to work with banks to convince them this is new technology, it’s going to work. How do you do that?

So much of what is built is what can be financed, and that’s been the tragedy of development in big cities for a long time.

Huh: This is where we understand the pressures and the risks associated with financing. We understand the banking side, I mean, having gone through venture and understanding just how much risk they’re willing to take and what the returns have to be. Looking at real estate, I have a much broader perspective now. That is: if you can reduce the risk, if you can underwrite the guarantee, then the economics start to work out because the banks care about risk.

Once you control for the risk, financing becomes easier. So if the bank knows that the technology and the savings, or our guarantee and our cost and schedule makes their risk less, they’re willing to loan to the developer.

The challenge of being an entrepreneur pioneering a new technology is that any snafu that goes public can be like… how many people die on the road every day, yet people are still driving. One death in a self-driving car and it was pretty much halted for six months. You are building homes, there is a very emotional component to it as well.

Huh: Our risks are very different than a self-driving car. Structurally, using conventional shell structure methods prevent that high-risk approach.

We’re using as much standardized approaches and patterns on the structure and the interior. We’re not reinventing the wheel there. This is where our software delivers those values, because we can say, “Those two walls are actually the same, we can prefab them exactly the same way.” In fact, it turns out 50 percent of the walls by surface area are exactly the same, and we should just turn them out.

Yarne: People fetishize technology and sometimes there’s a desire to use high-tech things just because they’re high-tech. The only time we’re going to do something out of the box is if we can show that it’s generating labor savings and efficiency on the site. Usually, that doesn’t mean some fancy material or some crazy thing. If you enter our job site, you’d notice it’s basically a lot of wood, and drywall, and conventional parts that are put together differently.

Is there a risk that your approach is going to lend itself to cookie-cutter development?

Huh: That’s where we and modular vastly differ. Our system can accommodate variations in design. There are definitely costs associated with weird angles and things like that, but we actually want to provide that as a feedback loop to the architect and the developer and say, “Is it worth it to you?” Because now you can actually calculate the cost of it almost in real time.

That developer gets to decide, is that bay window worth the extra $2 a gross square foot? — Michael Yarne

Yarne: We’re not saying to a developer, “Oh, you can’t do a jaggedy angled thing. If you love bay windows, that’s your thing.” What our system provides the developer is a real data-driven approach to make that tradeoff. That developer gets to decide, is that bay window worth the extra $2 a gross square foot?

How are you thinking about training? This is going to require quite a big change in things are done, and people in construction tend to be almost generational too, right?

Huh: We’ve certainly gotten the question of, “Why are you asking us to do it this way?” We have a facility in San Francisco where we actually had a mockup of a one-story structure. What happens is people come in and say, “Okay, alright, this is easier, but I can reduce the part count or I can make this better if I do it this way.” And we tell them, “Hey, the reason we do it this way is because it standardizes the rest of the building.” I know that we don’t need a three-inch cast iron pipe for DWV (Drain, Waste, Vent) up on the fourth floor. But that’s a standard size for us and we mass manufacture those, and that mass manufactured part is how we give you the productivity you need.”

You’re taking the romance out of construction, man. Come on.

Huh: That’s not the kind of romance I want.

(Write to Hiten at hs@therealdeal.com. To check out more of The REInterview, a series of in-depth conversations with real estate leaders and newsmakers hosted by Hiten Samtani, click here.)