Late one night last fall, eight flatbed trucks lined up at the foot of the George Washington Bridge and waited. When the clock struck midnight and they got the green light, the trucks crossed the bridge and snaked through Manhattan to Fort Greene, Brooklyn.

By late afternoon, a crane had lifted eight pieces of fully constructed apartments from the trucks and stacked them like Lego pieces on a vacant lot at 147 Saint Felix Street. A new three-story building was erected in less than a day.

The modular apartment building is a pilot program for Assembly OSM, a startup that hopes to perfect a high rise modular construction system that will enable faster construction, improve cost certainty and deliver higher quality buildings.

“It’s hard to build in a pocket like this,” said Assembly CEO Andrew Staniforth. “This site is on top of a subway in a landmarked district – there are a lot of constraints that mean the classic modular doesn’t work in a market like New York. What we focus on is how you reconcile customization and standardization and build tall.”

Assembly calls its construction method “post-modular” because it is more akin to a car or aircraft assembly line than a traditional modular build-out, where the structure is put together on a single factory floor.

The company instead spreads construction across a vast network of suppliers and manufacturers and then assembles them at its warehouse in Harrison, New Jersey. Assembly’s bathroom modules are from South Dakota, for example, while the floors are from St. Louis and the windows are from Poland.

“What it allows us to do is really maintain an efficient flow,” Staniforth said. “We’re just clipping into place rather than having to do construction under a roof which is the classic approach to modular construction.”

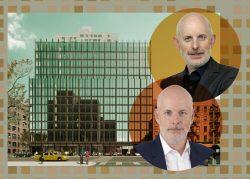

The Saint Felix Street development – which has two duplex apartments, a garage and a community space – is the test model for Assembly’s bigger 15-story apartment building at 247 117th Street in Harlem that is in planning stages. Assembly’s high-rise system can go up to 30 stories. Assembly says its method shaves a full year off construction.

“This was more expensive than if it was built as conventional because we’re trying out a bigger system,” said chief engineer Brian Sweeney. “This was our first time going through Department of Buildings approvals, our first time working with a general contractor, first time working with a different architect of record and an engineer of record. We wanted to get out of the prototype stage and get out into a real world scenario.”

Investors have lined up to bankroll Assembly’s vision: The startup has raised more than $60 million, including $38 million in Series A funding.

The company was founded in 2019 by twin brothers Bill and Chris Sharples, principals at Manhattan-based SHoP Architects, which also designed the ballyhooed B2 project, a 32-story modular tower abutting the Barclays Center that ran into significant problems. Staniforth worked at Forest City Ratner Companies, the developer of B2. Sweeney also came from SHoP.

Read more

The Saint Felix Street project still needs some finishes and a fresh coat of paint but Sweeney said he expects it to be finished in March.

“Part of what this building was for us is we needed to go through and figure out the logistics,” he said. “This project for us was the smallest building we could do that would validate all of this.”