Mexico-based fabrication and construction company FAME Building System is bringing their proprietary PVC and concrete building system to Florida, with an eye toward taking over the burgeoning monolithic concrete construction market. The PVC panels and concrete walls are perfect for the high humidity and storm-prone region, where traditional wood frame homes begin to buckle and rot nearly as quickly as they can be built, and FAMES’s unique fabrication system and distribution network is designed to facilitate high-quality construction at a fraction of the cost in money and manpower required for other building methods. FAME is erecting sample homes in South Florida as a launching pad for selling their construction system to local contractors, who will then be able to build homes using the system as well as materials manufactured by FAME in Mexico and shipped across the Gulf. The Real Deal sat down with FAME President Fabricio James Lujan and partner Enrique Requejo to learn more about the firm’s origins, the benefits of their PVC construction technology, and their plans for expanding into the United States.

Concrete and PVC: A Perfect Pairing

The first monolithic concrete houses were built by none other than Thomas Edison, who patented a primitive version of the system used today by FAME Building System way back in 1917. Long before the first PVC panel was created, people saw the benefits of setting forms and pouring concrete to create a single structure: with a little bit of planning, a strong, long-lasting building could come together in a matter of days and for a fraction of the cost in administration and materials. Fast forward to the 1980s, when James and the team at FAME Building System realized that the firm’s PVC panels would make the perfect forms and exterior facade for concrete extrusion construction: by combining this simple concept with high-tech PVC panels, FAME Building System brought this hundred-year-old technique into the 21st Century, and began building houses, hospitals, offices, and more across Central America and Mexico.

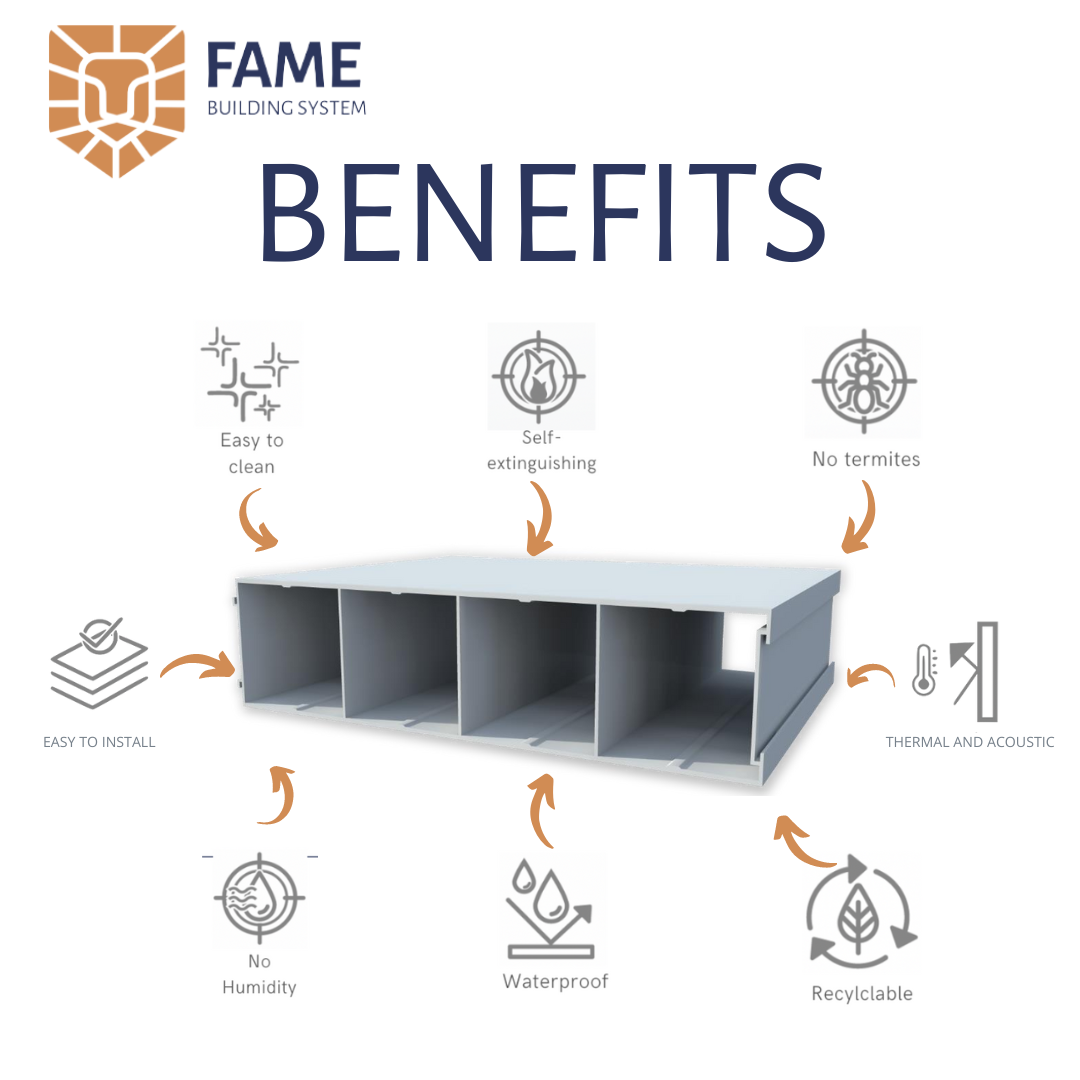

The benefits of the concrete construction system seen during the planning and construction process extend long past the building’s move-in date. “The concrete system is structurally robust against hurricanes and earthquakes,” says Requejo. “It also provides thermal insulation benefits, keeping interiors cooler and quieter.” Thanks to the flame-retardant and anti-bacterial qualities of PVC, FAME Building System’s buildings are also safer than a concrete home built using other facade materials. The buildings shine especially bright in humid environments like South Florida, where mold and termites can wreak havoc on timber frames within a few years of construction. Combine these qualities with a structure that can withstand gale-force winds and it makes perfect sense that this type of construction is catching on in the Sunshine State.

Eco-Friendly Construction at Scale

FAME Building System houses have macro benefits as well. By using virtually no wood during construction, the system preserves that increasingly rare (and expensive) resource; as Requejo says, “Wood for us is equal to oxygen, and we’re thinking of our planet first.” By manufacturing in the state of Yucatan and shipping the panels across the Gulf of Mexico instead of all the way from China, FAME’s “near-shoring” reduces the import time and fuel usage to below the industry average. Between the environmentally-friendly materials, lower heating and cooling costs thanks to concrete’s excellent insulation properties, and the antibacterial qualities of PVC, FAME Building System’s houses come out at being some of the lowest-impact, most energy efficient and comfortable options on the market.

What does FAME Building System’s building process look like in practice? James compares the actual assembly to working with Legos, with each of the panels fitting together with one another to create the building’s walls. The doors and windows are precut, making assembly as easy as dropping the panels into the correct place. Electrical wiring and plumbing is laid out at this stage as well, ensuring that these relatively fragile elements are encased in concrete and protected from hazards that can necessitate repairs down the road. Then, crews pour concrete into the panels to fortify the structure, creating a monolithic building that can withstand extreme weather conditions and temperature fluctuations far better than the typical wood frame house. After the concrete has set, crews can then install facade materials like sheetrock to complete the house, which, when complete, will look the same from the outside and inside as one made using wood while still benefiting from the thermal and antibacterial qualities of PVC and concrete. The panels come with a 15-year warranty, while the concrete itself will stand for a century without needing any maintenance.

Bringing FAME to South Florida

FAME Building System plans to build examples of their PVC and concrete homes in Rotonda West this quarter and use these proofs of concept to sell their construction system to builders in the states. These sample houses will be four-bedroom homes in a modern style and spanning about 3,000 square feet, and, when complete, will be indistinguishable from a standard timber-frame structure. Contractors who want to use the system will sign up for training with FAME Building System technicians and then buy the PVC panels directly from the manufacturer. Learning to build using this system is quick thanks to the prefabricated nature of each piece. “The panels are even numbered, to make installation quick and easy,” says James. Once builders have been trained and the panels have been delivered, contractors will see their costs plummet thanks to the efficiency of the construction system; for example, building a single room of 50 square meters takes two workers a mere two days.

James, Requejo, and FAME Building System are betting big on South Florida, which they hope will serve as a mere entry point into the United States market. With rising construction costs due to both labor and materials, FAME’s prefabricated panels and Lego-style assembly are poised to cut the Gordian Knot and usher in a new era of quick, inexpensive, robust, and environmentally responsible home construction. For contractors, being able to sell clients on structurally sound and maintenance-free homes without sacrificing aesthetics is a no-brainer, especially when paired with the cost-savings that come from reduced construction time and manpower needs. If you’re interested in working with FAME Building System in South Florida or elsewhere, reach out to fjames@famebs.com, crubio@famebs.com, csuarez@famebs.com today or visit their sample homes at https://www.famebs.com/